| Nominal Size | Pipe OD | Dimensions |

| mm/in | mm/in | L mm/in |

| 32x25 / 1 1/4x1 | 42.4x33.7 / 1.660x1.315 | 64 / 2.51 |

| 40x25 / 11/2x1 | 48.3x33.7 / 1.900x1.315 | 64 / 2.51 |

| 40x32 / 1 1/2×1 1/4 | 48.3x42.4 / 1.900x1.660 | 64 / 2.51 |

| 50x25 / 2x1 | 60.3 x 33.7 / 2.375x1.315 | 64 / 2.51 |

| 50x32 / 2x1 1/4 | 60.3x42.4 / 2.375x1.660 | 64 / 2.51 |

| 50x40 / 2x1 1/2 | 603x48.3 / 2.375x1.900 | 64 / 2.51 |

| 65x25 / 2 1/2x1 | 73.0 x 33.7 / 2.875x1.315 | 64 / 2.51 |

| 65x32 / 2 1/2x1 1/4 | 73.0x42.4 / 2.875x1.660 | 64 / 2.51 |

| 65x40 / 2 1/2x1 1/2 | 73.0x48.3 / 2.875x1.900 | 64 / 2.51 |

| 65x50 / 2 1/2x2 | 73.0 x 60.3 / 2.875x2.375 | 64 / 2.51 |

| 65x32 / 2 1/2x1 1/4 | 76.1 x 42.4 / 3.000x1.660 | 64 / 2.51 |

| 65x40 / 2 1/2x1 1/2 | 76.1x48.3 / 3.000x1.900 | 64 / 2.51 |

| 65x50 / 2 1/2x2 | 76.1x60.3 / 3.000 x 2.375 | 64 / 2.51 |

| 80x32 / 3x1 1/4 | 88.9x42.4 / 3.500x1.660 | 55 / 2.17 |

| 80x40 / 3x1 1/2 | 88.9 x 48.3 / 3.500x1.900 | 55 / 2.17 |

| 80x50 / 3x2 | 88.9 x 60.3 / 3.500x2.375 | 55 / 2.17 |

| 80x65 / 3x2 1/2 | 88.9x76.1 / 3.500 x 3.000 | 55 / 2.17 |

| 100x65 / 4x2 1/2 | 108.0 x 76.1 / 4.250 x 3.000 | 76 / 2.99 |

| 100x80 / 4x3 | 108.0x88.9 / 4.250 x 3.500 | 76 / 2.99 |

| 100x32 / 4x1 1/4 | 114.3x42.4 / 4.500x1.660 | 60 / 2.36 |

| 100x40 / 4x1 1/2 | 114.3x48.3 / 4.500x1.900 | 60 / 2.36 |

| 100x50 / 4x2 | 114.3x60.3 / 4.500x2.375 | 60 / 2.36 |

| 100x65 / 4x2 1/2 | 114.3x76.1 / 4.500 x 3.000 | 60 / 2.36 |

| 100x80 / 4x3 | 114.3x88.9 / 4.500 x 3.500 | 60 / 2.36 |

| 125x50 / 5x2 | 139.7x60.3 / 5.500x2.375 | 65 / 2.56 |

| 125x65 / 5x2 1/2 | 139.7x76.1 / 5.500 x 3.000 | 65 / 2.56 |

| 125x80 / 5x3 | 139.7x88.9 / 5.500 x 3.500 | 65 / 2.56 |

| 125x100 / 5x4 | 139.7x114.3 / 5.500 x 4.500 | 65 / 2.56 |

| 150x50 / 6x2 | 159.0x60.3 / 6.250x2.375 | 70 / 2.76 |

| 150x65 / 6x2 1/2 | 159.0x76.1 / 6.250 x 3.000 | 70 / 2.76 |

| 150x80 / 6x3 | 159.0x88.9 / 6.250 x 3.500 | 70 / 2.76 |

| 150x100 / 6x4 | 159.0x108.0 / 6.250 x 4.250 | 70 / 2.76 |

| 150x100 / 6x4 | 159.0x114.3 / 6.250x4.500 | 70 / 2.76 |

| 150x125 / 6x5 | 159.0x133.0 / 6.250x5.250 | 70 / 2.76 |

| 150x125 / 6x5 | 159 0x139 7 / 6.250 x 5.500 | 70 / 2.76 |

| 150x50 / 6x2 | 165.1 x60.3 / 6.500 x 2.375 | 102 / 4.01 |

| 150x65 / 6x2 1/2 | 165.1x76.1 / 6.500 x 3.000 | 102 / 4.01 |

| 150x80 / 6x3 | 165.1x88.9 / 6.500 x 3.500 | 102 / 4.01 |

| 150x100 / 6x4 | 165.1x114.3 / 6.500x4.500 | 102 / 4.01 |

| 150x125 / 6x5 | 165.1x139.7 / 6.500x5.500 | 102 / 4.01 |

| 150x50 / 6x2 | 168.3 x 60.3 / 6.625x2.375 | 70 / 2.76 |

| 150x65 / 6x2 1/2 | 168.3x76.1 / 6.625 x 3.000 | 70 / 2.76 |

| 150x80 / 6x3 | 168.3 x 88.9 / 6.625x3.500 | 70 / 2.76 |

| 150x100 / 6x4 | 168.3x114.3 / 6.625x4.500 | 70 / 2.76 |

| 150x125 / 6x5 | 168.3x139.7 / 6.625 x 5.500 | 70 / 2.76 |

| 200 x 50 / 8x2 | 219.1x60.3 / 8.625x2.375 | 85 / 3.35 |

| 200x65 / 8x2 1/2 | 219.1x76.1 / 8 625x3.000 | 85 / 3.35 |

| 200 x 80 / 8x3 | 219.1x88.9 / 8.625x3.500 | 85 / 3.35 |

| 200x100 / 8x4 | 219.1 x 108.0 / 8.625x4.250 | 85 / 3.35 |

| 200x100 / 8x4 | 219.1 x 114.3 / 8.625x4.500 | 85 / 3.35 |

| 200x125 / 8x5 | 219.1 x 139.7 / 8.625 x 5.500 | 85 / 3.35 |

| 200x150 / 8x6 | 219.1 x 159.0 / 8.625x6.250 | 85 / 3.35 |

| 200x150 / 8x6 | 219.1 x 165.1 / 8.625x6.500 | 85 / 3.35 |

| 200x150 / 8x6 | 219.1 x 168.3 / 8.625x6.625 | 85 / 3.35 |

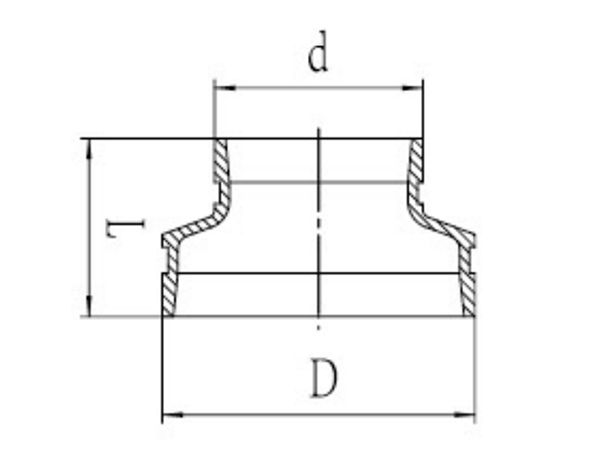

Grooved Concentric Reducer

Grooved concentric reducers are cone-shaped pipe fittings with grooved connections that reduce the size of a pipeline in a symmetrical and concentric manner, while keeping the centerlines of the two pipes aligned.

Features

Made of materials such as ductile iron, stainless steel, or carbon steel, providing high wear resistance and corrosion resistance.

Available in various sizes and pressure ratings to accommodate different applications.

Enables to join the two pipes of different diameters.

Recommended Applications

Grooved concentric reducer is commonly used in industrial and commercial piping systems, such as gas pipelines, water supply pipelines, etc., where a reduction of the pipe size is required to accommodate changes in flow or pressure.

Send Inquiry

Key Specifications

-

Available sizes: 1 1/4×1 inch~12×10 inch |DN32×25~DN300×250

-

Working pressure: 300PSI/2.07MPa

-

Certificate: FM/UL/CE certified

-

Coating: epoxy/galvanized

-

Color: red/orange/white, etc.

-

Material: ductile iron, stainless steel or carbon steel

Content